Masterbatch ipsum nigrum manufacturer

-

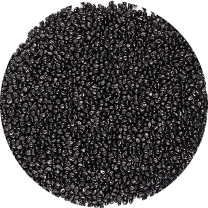

Ry-MMMCCIX Carbon Nigrum Masterbatch Dyestuff Granule pro plastic / HDPE / PE / Pp Fistulae

Ry-MMMCCIX Nigrum Masterbatch est processionaliter cum HDPE sicut carrier et excelsum puritatem ipsum Nigrum. Hoc pro

-

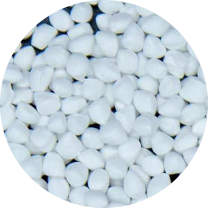

Pp Hygoenic / cibum gradu Eva / Abs / Petr plastic pellets nigrum masterbatch

Hoc productum est pp ut carrier et in linea cum FDA-certified pigmento ipsum nigrum processus, cum alto dispersionem,

-

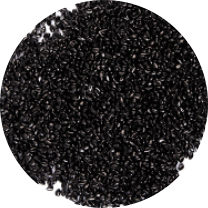

Agricultural film mulch nigrum masterbatch nigredo granulum glutas

Cum PE sicut in carrier, hoc productum est processionaliter cum pigmento ipsum nigrum, quod est maxime princeps dispe

-

Commune universae gradu granulis nigrum masterbatch nigrum plastic granulis

Hoc productum utitur lldpe ut tabellarius et processionaliter cum pigmento ipsum nigrum, quod habet dispersionem, alt

nobis loquere

qui sumus?

Changzhou Runyi Nova Materia Technologia Co., Ltd.

nostrum negotium socium

News

-

Scientia Nigrae: Optimizing Polymer euismod per Carbone...

Munus Engineering Magistri Carbonis Nigri In polymer industria, the ipsum nigrum masterbatch longe p...

discere plus -

Materia Scientiae pigmentationis: Compatibilitas assequ...

Delectu a Carbon Niger Masterbatch est technica exercitatio quae longe supra colorem adaptat. Processus...

discere plus -

Machinator Longevitatis: Carbon Black Masterbatch UV St...

In applicationibus quae exigunt effectum velit extensum, sicut fistulae, geosyntheticae et membranae agriculturae — f...

discere plus -

Subtilitas pigmentationis: Dominatio FPV et Dispersio C...

Processus enim in fabricandis membranarum tenuium, fibrarum subtilium, vel injectiones urbanarum partium formatarum, ...

discere plus

scientia industria

Carbon Nigrum Masterbatch Technology Analysis: Quam ad consequi princeps disperii et firmum coloring?

Carbon Nigrum Masterbatch (Carbon Nigrum Masterbatch) Est unus de maxime late solebat colorantes et eget additives in plastics industria. Et Core provocatione est solvere dispersionem problema causatur a summo specifica superficiem area et facilis Agglomeration characteres de Carbon Nigrum, dum ensuring color stabilitatem et functionality (ut conductivity, UV stabilitatem et functionality (ut conductivity, UV stabilitatem et functionality (ut conductivity, UV stabilitatem et functionality (ut conductivity, UV et functionality (ut conductivity, UV stability et functionality (ut conductivity, UV et functionality (ut conductivity, UV et tutum). Et haec est clavis technica puncta ad consequi princeps disperii et firmum coloring:

I. Key factors pro dispertibility Carbon Nigrum Masterbatch

I. Electio Carbon Nigrum

Particula magnitudine et structuram:

Minores particula magnitudine (ut 20-30nm) fortior coloring potestate sed maiorem difficultatem dispersionis (facile agglomeratum).

Altus-structuram ipsum Nigrum (DBP oleum effusio valorem> 120ml / 100g) est facillimus ad formare a PROLIXUS Network, sed requirit fortior tondendas vi dispergere.

Superficiem eget modificatio:

Oxidatio-tractata Carbon Nigrum (quibus carboxyl / hydroxyl coetus) can amplio compatibility cum Suspendisse portarent (ut PA, PEK).

II. Matching de carrier resinam

| Resin type | Commendatur ipsum Nigrum concentration | Characteres |

|---|---|---|

| Ldpe | 20-30% | Minimum processui temperatus (160-200 ° C), optimum ad conflandum fluxus, idoneam ad generalem propositum coloring masterbatch. |

| Pp | 25-40% | Exigit altum tondendas vim (220-250 ° C), ideal ad altus-concentration PROLIXUS Masterbatch, optimum æstus resistentia. |

| HDPE | 20-35% | Maxime rigiditatem apta iniectio coronam, sed requirit diligenter dispersionem vitare superficiem defectus. |

| PS / abs | 15-25% | Minus processus temperatus (180-220 ° C), requirit lubricants (E.G .: EBS) ut ne Degradation. |

| PA / Pet | 15-30% | Requirit superficies-mutatio carbonis nigrum (oxidized), compatible cum Suspendisse Resinam, in Engineering Plastics. |

III. Dispersants et dispensando AIDS

Dispersants:

Minimum M. pondus Polyethylene cera (PE cera) et Steerates (ut ZNSt) potest reducere ad adsorption inter ipsum nigrum particulas.

Superdepersants (ut byk-MMCL) tunica Carbon Nigrum cum anchoring coetus ad amplio diu-term stabilitatem.

Lubricants:

Ethylene bissteeramide (EBS) reduces conflandum Viscosity et prohibet screw slippage.

IV. Processing Technology Optimization

Didymus cochlea Extrusion Processus:

Summus aspect Ratio (L / D≥40) combined screw elementis (egenis cuneos, vicissim relatorum) enhance tondendas dispersionem.

Temperature Zoning Imperium (ut PP-Based Masterbatch, 180-220 ℃).

Masterbatch Dilore Ratio:

Fere, I% ~ V% Praeterea commendatur, et PROLIXUS Masterbatch indiget esse altior (X% ~ XX%).

II. Key potestate punctorum ad firmum coloring

I. color consistency

Carbon Nigrum concentration et L * A * b * Value: Usus spectrophotometer ad Monitor in nigredo (L * value

II. Adaptability ad applicationem missionibus

Outdoor Tempestas resistentia: Carbon Nigrum se habet UV absorption facultatem, sed opus est ad matched cum lux stabilitorent (ut impedivit Amine hals).

Contact OPPERIBUS: Carbon Nigrum exempla Models, qui propinquosce cum FDA XXI Cfr 178,3297 vel EU 10/2011 (ut Cabot Monarcha DCCCLXXX).

III. Commune problems et solutions

| Exitus | Caussa | Solution |

|---|---|---|

| Arietty superficies in Masterbatch | Pauper Carbon Nigrum Dispersio | Auget tondendas temperatus in stupra zonas aut addere magis dispersio agente (E.G .: PE cera). |

| Greyhcus Tint in ultima products | Satis ipsum nigrum concentration aut resin degradation | Reprehendo Masterbatch Dilution ratio et processui temperatus terminum. |

| Effusus conductivity | Carbon Nigrum structuram damnum vel inaequalis distribution | Optimize screw configuratione ne nimia tondendas; Uti summus structuram ipsum nigrum. |

| Colo colui cultum sanguinem / migratio | Minimum Molecular pondere carriers vel nimia plasticizers | Switch ad altiorem-mw resins (E.G., HDPE loco LDPE) vel redigendum plasticizer contentus. |

| Reducitur mechanica vires | Overloading de Carbon Nigrum (> XL%) Disrupting Polymer Matrix | Libra Carbon Nigrum Content Cum ReinForcing additives (E.G .: Vitrum fibris pro PA) . |