| Carbon Nigrum Content | XXX% - L% | Fusce secundum demanda |

| Carrier | PE / PP / PS / abs | Compatible cum universali Polymers |

| INDEX | V - XXV | G / 10min (Exertus quod per ASTM D1238) |

| Densitas | 1.2 - 1.4 | G / CM³ |

| Dispersio campester | Praeclarus | Iudicum ISO signa ad uniformitatem |

| Calor resistentia | ≥300 | ℃, non corrumpuntur per altus-temperatus processui |

| Luxus | ≥7 | Blue lana scale (1-8 levels) |

| UV resistance | Altum | Idoneam pro longum differentur velit usus |

| Dosis | I% - V% | Adjust fundatur in color profundum et applicationem |

| Humorem content | ≤0.1 | %, Ensures aridam statum |

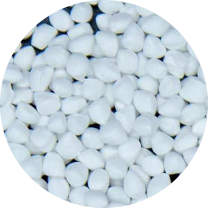

| Particula magnitudine | II - III | mm uniformis granulis facile processus |

Commune universae gradu granulis nigrum masterbatch nigrum plastic granulis

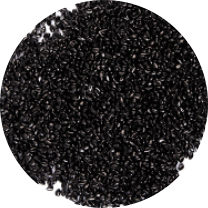

Commune universae gradu granulis nigrum masterbatch nigrum plastic granulis Sunt late solebat colorant, maxime solebat providere firmum et consistent nigrum effectus in variis plastic products. Hoc nigrum masterbatter habet proprietas fortis versatility et late applicability, et potest esse mixta cum varietate plastic rudis materiae ad occursum coloring necessitatibus diversis agris. Ordinarius generalis-proposito Nigrum Masterbatch Black plastic particulas sunt in packaging, in domum suamplianit, automobiles, aedificium materiae et alia industries. Potest adhiberi variis nigrum plastic products, ut packaging sacculos, vasis, conchas, partes, etc.

describere

Hoc productum utitur lldpe ut tabellarius et processionaliter cum pigmento ipsum nigrum, quod habet dispersionem, altum nigrum et altum claritas. Potest esse in LDPE, LLDPE, PP, PA, Abs, Abs / PC Alloy et alia REDIVIVUS materiae, cum summus sumptus perficientur.

XXV kg / sacculum compositum packaging peram. Store in sicco est.

Commendatur repono period: Si condita instructus, usque ad unum annum, magis quam anno post, commendatur ad re-test humorem contentus ante usum.

Communis universae gradu granulis nigrum masterbatch , Universalis gradu Nigrum Masterbatch, est plastic granulari materia ex polymer per addendo ipsum Nigrum, dispert et alia additives. Hoc nigrum masterbatch est maxime usus est in colorant et eget et emendare ad productionem plastic products ad amplio apparet qualis et quaedam proprietatibus plastic products.

Features:

Optimum coloring possessiones: providet altum, uniformis nigrum effectus cum princeps latebat potestate et boni gloria.

Fortis versatility: apta varietate polymer subiecta, inter PE (polyethylene), pp (Polypropylene), Ps (Polysestyrene), Abs, etc.

Optimum processus perficientur particulas uniformis facile dispergere et non afficiunt mechanica proprietates plastic subiectum.

Environmentally amica Formula: Non-toxicus et innoxia, in obsequio cum pertinet environmental tutela et cibum contactus salutem signa (si certified, placere indicant).

Excelsus sumptus euismod: humilis dosis, significant coloring effectus, et reducitur vastum rudis materiae.

Applicationem scope et missionibus:

Plastic packaging industria:

Ad producendum nigrum plastic sacculos, quisquiliarum sacculos et packaging films.

Packaging in cibaria Packaging Lorem (oportet propinquis pertinet salus signa).

Genus appliances et electronic productum casings:

Usus in fabricare de familia appliances (ut televisions, refrigerators, baptismata machinis, etc) et electronic apparatu casings providere altum et matte effectis et amplio species qualitas.

Auto Industry:

Usus est in colorant in automotive interiora, Dashboards, bumpers et aliis partibus providere UV resistentia, æstus resistentia et tempestate resistentia.

Agriculturae applications materiae et aedificationem:

Est idoneam ad productio plastic fistulae, funem vaginae, Geomembres, CONSERVATORIUM films et alia products, cum bono diuturnitatem et anti-canus proprietatibus.

Daily Consumer bona:

Usus ad cotidie necessitatibus ut plastic hydrias, crateros, pocula, stationery, etc. ad augendae visual appellatio products.

Industrial vasa:

Cum in eget repono obterere, plastic pallets et alia products, potest providere anti-stabilis et anti-corrosio functiones (correspondentes additives opus ad additum) .

nobis loquere

qui sumus?

Changzhou Runyi Nova Materia Technologia Co., Ltd.

Changzhou Runyi Nova Materia Technologia Co., Ltd. sic

Lupum Commune universae gradu granulis nigrum masterbatch nigrum plastic granulis elit et

Lupum OEM/ODM Commune universae gradu granulis nigrum masterbatch nigrum plastic granulis officinas. Investigationem et progressionem instituimus pro pannum inceptis ex 2020 liquefactis, et in multiplicibus lineis productionis investitum pro panno liquefacto magisterbatch nigro, magisterbatch electreum oleum, magisterbatch electreum fluorocarbon polymerus, et aqua electra masterbatch. Nostra societas carbonis producti nigri et electrodes producuntur secundum signa internationalia. Ut ad forum postulatum, novas varietates augere pergimus, strenue ad processuum productionis et armorum emendationem conferunt et simul industriam conservant, consumptionem minuunt et ambitum quam maxime in productione processu tuentur. Ex principiis probitatis et fidei, conciliationis cooperationem ac principia technologicae innovationis et excellentiae, societas diuturnum et bonum cum multis inceptis necessitudines cooperativas constituit.

-

0m²

Anhui officinas

-

0m²

Changzhou officinam

-

0+

Movere-in tempore

-

0+

annui output

-

0+

signa patented

-

missio

Diuturnum tempus et bonas necessitudines cooperantes cum multis inceptis statuimus.

-

Visio

Commissum fieri solutionem altiore provisor viridis packaging in industria.

-

values

Integritas et fides, libens cooperatio.

-

codicem conductum

Innovatio technica et praestantia sunt principia evolutionis.

societas cultura

Comprehensive intellege societatem, clientes veras sentiant, et intentiones inquisitionis augeant.

News

-

Scientia Nigrae: Optimizing Polymer euismod per Carbonem N...

Munus Engineering Magistri Carbonis Nigri In polymer industria, the ipsum nigrum masterbatch lo...

discere plus -

Materia Scientiae pigmentationis: Compatibilitas assequend...

Delectu a Carbon Niger Masterbatch est technica exercitatio quae longe supra colorem adaptat. Proc...

discere plus -

Machinator Longevitatis: Carbon Black Masterbatch UV Stabi...

In applicationibus quae exigunt effectum velit extensum, sicut fistulae, geosyntheticae et membranae agricultura...

discere plus -

Subtilitas pigmentationis: Dominatio FPV et Dispersio Carb...

Processus enim in fabricandis membranarum tenuium, fibrarum subtilium, vel injectiones urbanarum partium formata...

discere plus -

MFR Matching Principium: Optimising White Masterbatch and ...

In regno polymerorum processus, assequendi constantiam coloris dispersionis et qualitatem producti immaculatam o...

discere plus -

Achieving Ignitus Quality: An ipsum ducem TiO2 dispersio i...

Introduction: The Business Case for Perfect Dispersion Nam B2B artifices in materia plastica industria, quali...

discere plus

Commune universae gradu granulis nigrum masterbatch nigrum plastic granulis Industria scientia

Nigrum Masterbatch: Quid faciam additives et carrier resins augendae plastic products?

Nigrum Masterbatch Serves ut crucial component in plastics industria, enabling efficiens et efficax coloring de plastic products. Central ad functionality sunt additives et carrier resins continet.

Additives in universali Nigrum Masterbatch

Additives Play a Pivotal Partes in Universal Nigrum Masterbatter formulations, offering variis enhancements ad extremum plastic uber. Haec additives sunt diligenter lectus secundum specifica requisitis ad applicationem et desideravit proprietatibus finis uber. Quidam commune additives in universali Nigrum Masterbatch include:

UV Stabilizers: UV stabilizers protegat plastic products ex degradation causatur a nuditate ad ultraviolet (UV) radialis, ita extendens suum servitium vitae et maintaining eorum aesthetic appeal.

Antioxidants: Antioxidants inhibere oxidatio de plastic materiae, quae potest ducere ad color, fragtilitatem et degradationem in tempore. Per incorporating Antioxidants, Masterbatch Manufacturers augendae diuturnitatem et Vivacitas de plastic products.

Antistatic agentia: Antistatic agentibus redigendum in buildup de static electricity super superficiem plastic products, ne pulvis cumulus et melior eorum altiore munditiam et speciem.

Labi agentibus: labi agentibus redigendum coefficiens friction inter plastic superficies, facilius facilius tractantem, dispensando et packaging de plastic products.

Flamma retardants: Flamma retardants impertit igni resistentiam plastic products, reducendo periculum ignitionem et inhibentes in extendens flammis in eventu ignis.

Processing AIDS: Processing AIDS amplio fluxus proprietatibus plastic resins in vestibulum processus ut extrusionem, iniectio CUMATIUM, et ictu CUMATIUM productum qualis.

Carrier Resens in Universalis Nigrum Masterbatch

Portitorem resinam serve sicut vulvam in quibus additives et colorants dispersi uniformiter ad masterbatch. Selectio carrier resins dependet factores ut compatibility cum basi polymer, dispensando conditionibus et desideravit proprietatibus ultima plastic uber. Communis genera carrier resens usus est in universali Masterbatch includit:

Polyethylene (PE): PE-fundatur carrier resins sunt late in universali nigrum masterbatter formulations ex eorum optimum compatibility cum varietate basis polymers, inter polyethylene, ethylene, vinyl acetate, et ethylene-vinyl acetate, et ethylene-vinyl acetate Copolymers, ethylene-vinyl

Polypropylene (PP) PP-fundatur carrier resins offer bonum scelerisque stabilitatem, mechanica vires et eget resistentia, faciens ea idoneam ad applications requiring superior temperatus processus et perficientur applications requiring superior temperatus processus et perficientur.

Polystyrene (Psal): Ps-fundatur carrier resins sunt communiter in applications in quo claritatem, rigorem, et dimensional stabilitatem sunt paramaunt, ut cibum packaging et dolor bona.

Polyvinyl Chloride (PVC): PVC-based carrier resins are preferred for applications requiring excellent weatherability, chemical resistance, and electrical insulation properties, such as building materials, automotive components, and electrical cables.

Ethylene-vinyl Acetate (EVA): EVA-based carrier resins offer flexibility, low-temperature toughness, and good adhesion to various substrates, making them suitable for applications requiring softness, elasticity, and adhesion, such as flexible packaging and footwear.

Productio processus et qualitas imperium

Et productionem universae Nigrum Masterbatch involves methilaricosis imperium formula, miscentes, componendo et pelletizing processus ut ad uniformis dispersionem additives et colorants intra carrier resinam matricem. Qualitas mensuras sunt implemented ad omnem scaenam productio ad monitor clavis parametri ut pigment concentration, dispersionem qualis, pellem magnitudine et humorem content.