Iniectio fingens masterbatch album manufacturer

-

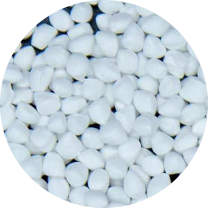

Iniectio CUMATIUM Alba Masterbatch Alba Iniectio Plastic Granula

Hoc productum est lldpe ut tabellarius et Rutile Titanium dioxide dispensando, cum dispersionem perficientur, princep

nobis loquere

qui sumus?

Changzhou Runyi Nova Materia Technologia Co., Ltd.

nostrum negotium socium

News

-

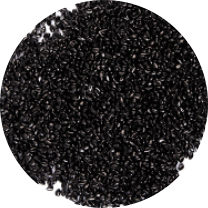

Scientia Nigrae: Optimizing Polymer euismod per Carbone...

Munus Engineering Magistri Carbonis Nigri In polymer industria, the ipsum nigrum masterbatch longe p...

discere plus -

Materia Scientiae pigmentationis: Compatibilitas assequ...

Delectu a Carbon Niger Masterbatch est technica exercitatio quae longe supra colorem adaptat. Processus...

discere plus -

Machinator Longevitatis: Carbon Black Masterbatch UV St...

In applicationibus quae exigunt effectum velit extensum, sicut fistulae, geosyntheticae et membranae agriculturae — f...

discere plus -

Subtilitas pigmentationis: Dominatio FPV et Dispersio C...

Processus enim in fabricandis membranarum tenuium, fibrarum subtilium, vel injectiones urbanarum partium formatarum, ...

discere plus

scientia industria

Clavem perficientur Indicatores et lectio dux ad Iniectio CUMATIUM Alba Masterbatch

I. Analysis de Core perficientur Indicatores

Albedo et latebat potestatem

Titanium dioxide (TIO₂) Content: Usually XX% ~ L% (rutile genus est melius), directe afficiens albedo et latebat potestate.

Test Latin: Quantus ISO MMCDLXX (Blue lux albedo) vel Hunter Lab valorem, altum albedo postulo ut ≥95% (ut cotidie necessitatibus, electronic housings).

Uniformitas dispersio

Carrier resina compatibility: opus ad aequare subiecti (ut Pp, Abs, HDPE, etc.) Ad vitare inaequalis dispersionem debitum ad verticitatem differentias.

Aestimatio modum: observe Masterbatch crustae sub microscopio et non visibilis particula agglomeration est qualified.

Index liquescens (MFI) matching

Iniectio CUMATIUM processus requisita: Masterbatch MFI debet esse proxima ad subiectum resinae (± X%) ut ne fluxus differences ex causando fluxus marcas et color differences.

Test Conditions: exempli gratia, Pp Substrate sunt communiter ad CCXXX ℃ / 2.16kg (ASTM D1238).

Calor resistentia et stabilitatem

Decomposition temperatus: necessitates esse altior quam iniectio caniendo temperatus (ut Pp processui circiter CC ~ CCXL ℃, masterbatch necessitatibus ad resistere plus quam CCL ℃).

Flaventia periculo: aestimare color mutatio Δe <1.5 per calor senescentis test (ut CL ℃ × 4H).

Mechanica proprietatibus

Impact et Tensile Vitibus: High-Repleti Masterbatch potest reducere ad lenta subiecti, quod necessitates ad compensatur addendo elastomers (ut Poe immutatio).

II. Key factors in Lorem

Substratum resin type

Polarity matching: ABS Masterbatch utor San Carrier: et PP Masterbatch commendat Polypropylene Portitorem.

Casus: Food packaging pp products eget FDA-certified masterbatch ad vitare migrationem contaminationem.

Terminal application missionibus

High tempestas resistentia requisita (ut velit products) Elige Rutile Titanium dioxide UV stabilitor.

Tenues Wall Products: High Flow Masterbatch (MFI> 20g / 10min) reducit iniectio defectus.

Sumptus Optimization Strategy

Titanium dioxide Alternative: Composite Filllers (ut Barium Sulfate Titanium Dioxide) reducere costs, sed albedo necessitates ad libratum.

Insuper Ratio: Usually I% ~ IV%, princeps latebat masterbatch potest reducere dosage ad 1.5%.

III. Solutions ad communis problems

Colore Difference: Reprehendo in stabilitatem Masterbatch batch (Titanium Dioxide particula mole distribution ≤ 0.3μm) et iniectio temperatus fluctuationem.

Fluunt marcas / Silver Streaks: auget Feecke temperatus aut switch ad humilis tondendas masterbatter formula.

Praecipitation Migration: Select High M. Weight Carrier Resina (ut altum liquescit Index Pp) ad amplio Compatibility.